Intelligent collaboration between humans and robots can exploit high potential. The aim is not to replace workers, but to close existing process gaps and make complex processes manageable by means of valuable user feedback. Organisational management of hyperautomation has an important role to play in our approach to hyperconnectivity transformation.

Whenever procedures prove their value in a successful company, they should be formalized over time as the company’s proprietary processes. To a certain extent, this happens completely organically. To remain fast and effective despite the processes set up for specific purposes, however, it is advisable to focus on the partial automation of various processes and to anchor it in the strategic goals. This is where robotic process automation (RPA) has proved to be a technology recognized throughout the industry that can quickly automate isolated processes by simple means.

Nevertheless, this type of automation often cannot be integrated end-to-end into existing business processes because of high levels of complexity, leading to a loss of scaling potential during implementation. Furthermore, the ongoing maintenance of the previously implemented processes is extremely costly once a critical mass has been reached.

Hyperautomation is the next evolutionary step towards full automation and combines RPA with smart technologies. Simple RPA components are enhanced with artificial intelligence, process mining, and other integrated advanced analytics tools, creating precisely the process chain that is expected to contribute to the end result. Along with the mapping of mouse and keyboard actions previously performed manually, a software robot can also make decisions based on statistical models, for example. The resulting degree of automation exceeds the potential of simple process automation many times over.

According to Gartner, hyperautomation is a concept, or rather a condition, that companies require to secure their future competitiveness. It promises organizations a higher degree and depth of automation (i.e., automation of complex issues as well) and greater agility in process optimization and process configuration. In brief, hyperautomation falls in the purview of management, must be approached holistically, and should be anchored in the strategy.

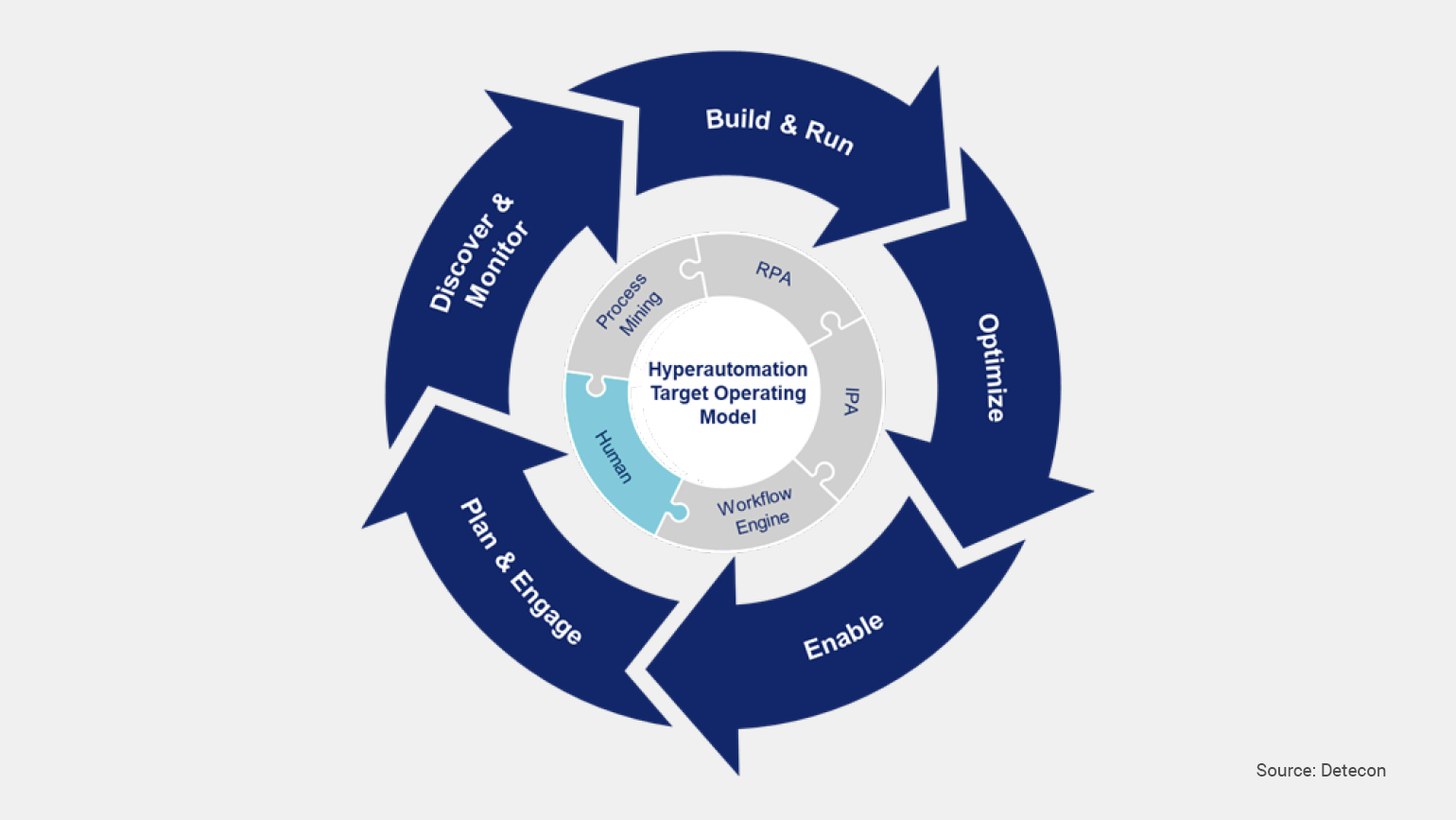

Ideally, hyperautomation is integrated through the use of iterative building blocks to shift focus from the large overall process to smaller and smaller sub-processes, a means of ensuring scalability. The result is always the coupling of a process with an automation component. The key control point here is the target operating model (TOM), which is the origin of the attractive force that binds all the components together. Besides central governance, the TOM anchors the reuse of components, the bundling of competencies, and other organizational building blocks.

Specifically, the automation cycle runs through the following phases:

1. Discover & Monitor

The first step is to determine the right starting point for automation. This is achieved by analyzing the potential of an initial process in the Discover & Monitor phase by means of process mining. The direct link of process mining software to current systems enables detailed evaluations of the process workflow. For example, the time required for execution of a process and the behavior of the dwell time in the related systems can be assessed. It must be kept in mind here that process mining does more than just capture a snapshot of the current status. On the contrary, it creates an instrument for the continuous monitoring of the quality of the examined process. Without this instrument, measures carried out at a later date cannot be evaluated.

Companies with especially high awareness of their own processes and their throughput times often know where there is a particular need for optimization. In any case, process mining generates important information that allows goal-oriented and quantifiable automation decisions to be made. Deciding which tools are used in this process step depends to a large extent on the specific situation of the company and must always be evaluated precisely. One example: the period between receipt of an order and start of production is of interest to a manufacturing company. Another example is the turnaround times for approvals within established approval processes.

2. Build & Run

In most cases, business processes are supported by several applications. If there are no dedicated interfaces already in place between such applications, automation can be developed to cross these boundaries. Robotic process automation handles this task by configuring virtual software robots that operate applications like human users, but work significantly faster and without taking any breaks. Proof-of-concept implementations of smaller sub-processes enable rapid production tests in the company to determine robustness, recoverability, and handling of RPA applications. A major element at this stage is the limiting of user expectations because, in their raw form, robots are “dumb.” Without human assistance, robots will not learn how to carry out human transfer actions that have not been defined in the process and in the corresponding program code. The decision as to whether the development and operation startup takes place in the pertinent business department in the form of self-service or is handled by the company’s own IT division depends on the target operating model.

3. Optimize

The goal of optimization is the continuous check of processes for scalability and the ongoing incorporation of changes into operations. If this does not happen, there is a risk that employees will drop automation and start creating their own processes again. New technologies, above all within the framework of artificial intelligence, promise enormous increases in process efficiency and quality. As the time scale continues to increase, intelligent automation will become a mandatory element for every company. The TOM has the tasks of maintaining an updated map of the most current status by means of a continuous process review and of using this mapping procedure to strive to implement the optimizations on its basis.

4. Enable/Integrate

The entire technology chain can often be implemented using so-called “low-code” scripts consisting of predefined application blocks. User-friendly tools have greatly reduced the level of development expertise required. Nevertheless, end users as the triggers of an automated sub-process should not come into contact with technological components and, if possible, should not be ripped out of their familiar working environment. A workflow engine is the means by which process mining, including intelligent process automation components, can be integrated by the employment of user-friendly process maps on a central platform. This is where automation can be launched, monitored, and optimized through expert feedback from users. The integration of the different technologies opens the door to smart end-to-end automation and provides a digitalized image of the business processes in the sense of a “digital twin.”

5. Plan & Engage

Plan & Engage relates to the often forgotten, and yet most important component in automation initiatives: people. Stakeholder collaboration is a top priority in all hyperautomation phases. Before the automation loop restarts with the Discover & Monitor phase, the collaboration between man and machine should be secured first and foremost. Companies that introduce intelligent automation with the primary goal of replacing employees will achieve only short-term productivity gains. The far greater purpose is to illustrate clearly the benefits, to support changes in people’s working methods, and to adapt business processes appropriately. Valuable user feedback should be continuously incorporated into the planning process of hyperautomation iterations.

6. TOM Implementation

Developing a hyperautomation strategy and the target operating model (TOM) is a critical step for sustainable and scalable integration of intelligent processes. The hyperautomation cluster organizes itself on the basis of corporate management principles, thereby structuring the elements necessary for implementation such as agile steering functions of project management and governance. Change management should also play a central role in all activities. This includes in particular the targeted training of employees to complement, not replace, their skills with those of intelligent machines.

Training intelligent agents

Employees should be able to teach intelligent agents new skills. Training is important to perform well in AI-enhanced processes. Employees who act as digital stewards ensure that their companies’ AI systems are used responsibly and not for illegal or unethical purposes.

Companies that use machines simply to displace employees through automation will miss out on the full potential of AI. A strategy of this type is doomed to failure. Tomorrow’s leaders will instead be those who embrace collaborative intelligence and transform their business activities, their markets, their industries, and, no less importantly, their workforces.