Wars, pandemics and rising energy prices are just three examples of current global crises with an enormous impact on the world economy. Long-term challenges such as climate change, raw material shortages or labour shortages overlay the crisis as the norm. This requires a radical rethink in the strategy and planning departments of companies. The most crisis-prone part of the entire value chain is the supply chain. We show how you can make your supply chain transparent, resilient and sustainable with digital technologies, using an example from telecommunications.

When supply chains are interrupted, they are a burden on any customer-oriented provision of products and services. The cause lies in the previous orientation of the supply chain: highly efficient and cost-optimised. In many industries, this means the implementation of the "just-in-time" principle: delivery according to time requirements while avoiding inventories - the warehouse is the truck, the ship, the plane. Parts or services are purchased at the most cost-effective location.

Realignment of the supply chain required

This principle must be questioned under the impression of interrupted supply chains and requires the search for a "crisis-proof" design. "Just-in-time" is supplemented or replaced by "just-in-case", depending on the industry. Companies need to factor in possible supply chain disruptions by building up inventories for critical parts. In addition, redundancies are built into the supply network, e.g. by considering alternative suppliers in other regions or in their own country. In addition, there are changing requirements from governmental or supranational bodies with regard to climate protection and sustainability as well as rising energy costs.

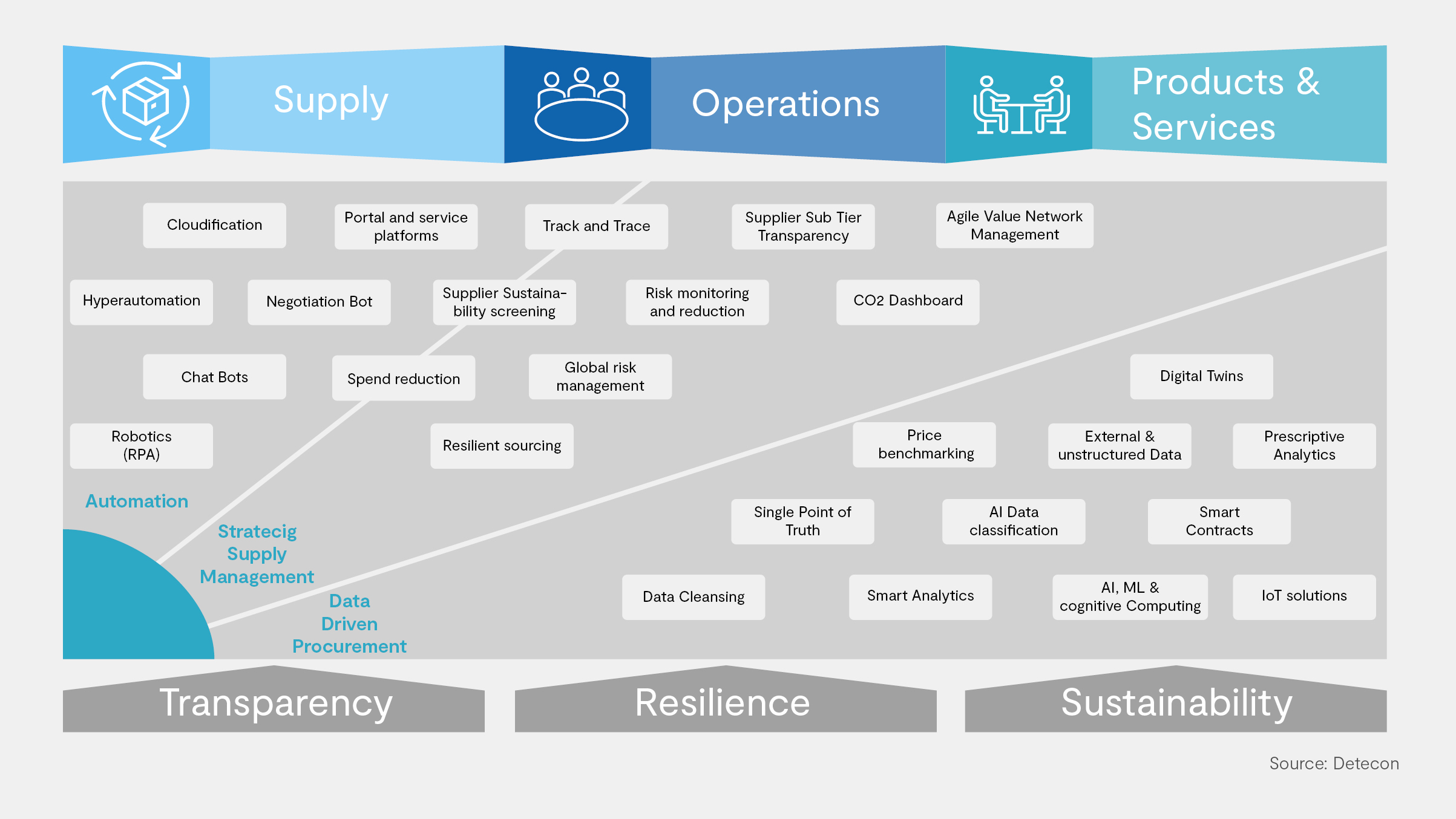

All these requirements necessitate a realignment of the supply chain, with three factors in particular determining this realignment:

-

(real-time) transparency with regard to several dimensions - temporal and local availability of parts as well as the structural set-up of the supply network (critical suppliers and sub-suppliers)

-

resilience with regard to a (cost-) optimal hedging of possible risks in the entire supply network - if necessary, a thus changed SCM strategy.

-

Sustainability to reduce rising energy costs and to meet increasingly stringent environmental standards.

The success of this reorientation depends on the use of digital technologies in combination with the integration of these technologies into the organisation and processes of a company's supply chain.

Digital technology as a success factor

Digital technologies in supply chain management are already technologically advanced and can be integrated. So far, however, this use has not yet become widespread because the necessity was not seen and the costs were not offset by sufficiently positive benefits. However, this has changed fundamentally with the emergence of various crises. The high costs incurred along the entire value chain due to interrupted supply chains make the use of technologies to create end-to-end transparency and resilience in the supply chain seem sensible.

Based on technologies such as IoT sensors, parts and transports along the entire supply chain can be tracked in real time, their position and condition monitored and their energy consumption optimised. Using solutions based on technologies such as Big Data and Artificial Intelligence, it is possible to process internal purchasing and planning data with external - structured and unstructured - data from partners and suppliers. The introduction of "digital twins" that digitise the entire chain enables effective risk management.

With the introduction of these digital technologies, the key challenges facing supply chain management in many industries can be effectively managed in the future:

-

Early identification of risks in the supply chain and planning adjustments based on the simulation of scenarios such as the "digital twin"

-

Real-time detection of disruptions in the supply chain and their (automated) elimination with solutions such as "condition monitoring"

-

Forward-looking analyses that provide more reliable information on future demand and the development of (commodity) prices through solutions such as Spend Analysis and Monitoring

The implementation of digital technologies in the supply chain cannot be done in isolation, but requires a transformation of the supply chain organisation and must have the entire supply chain in mind. This means that appropriate steering committees, processes and capabilities must be established within the organisation (purchasing, logistics) to enable the effective use of digital solutions.

Digital networking of partners is required across the supply chain. Today, this is no longer a technological challenge based on cloud platforms and APIs. Rather, the organisational, procedural and cultural barriers between the participants in the supply chain must be overcome to enable the end-to-end networking of data.

Focus on risk management: the example of telecommunications industry

The supply chain of the telecommunications industry has been particularly affected by political crises in recent years, which have led to a shortage of chips and raw materials in particular. This affects both the provision of services based on infrastructure and the provision of end devices to their customers. Therefore, a rethink has begun, which has led to the use of comprehensive risk management.

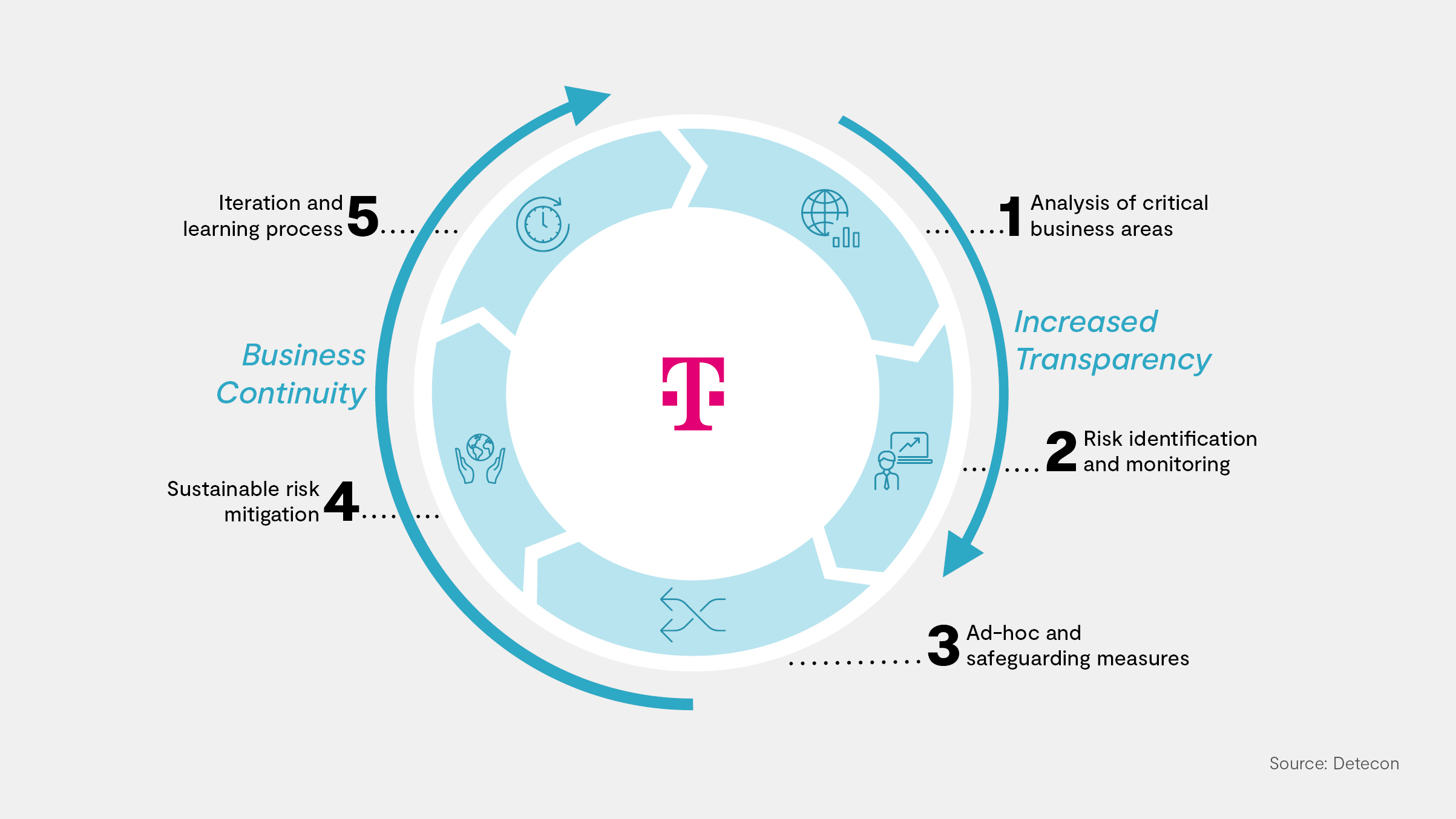

By means of the introduction of risk management tools in combination with solutions of a smart spend analysis, which includes the analysis of suppliers, risks in the supply chain can be identified at an early stage and planning can be adjusted accordingly. This also includes the implementation of a risk management process cycle to manage risks in a structured and systematic way:

-

Analysis of critical parts and services

By means of a structured evaluation of the parts and services to be procured with regard to their market complexity and their criticality to the business, critical parts such as switches or mobile end devices are identified. Most importantly, the prioritisation of services and the organisational alignment of these priorities in terms of "business continuity". A cost structure analysis of these parts also makes it possible to identify the preliminary products (e.g. semiconductors) and raw materials (e.g. lithium) and to include their suppliers in the risk management.

-

Identification and monitoring of risks

The use of digital tools for analysis based on internal and external data (real-time supply chain data, unstructured data from the web) enables risks such as future raw material shortages or the failure of semiconductor suppliers to be identified and the impact on the company to be assessed. This assessment is done using a risk framework to evaluate the likelihood of risks occurring and their impact on the business.

-

Implementation of ad-hoc measures to safeguard the ability to deliver

The derivation of short-term measures, such as the stockpiling of additional semiconductors ("just-in-case"), is based on the evaluations of the risk analysis in combination with the analysis of previous expenditures, future planning, contingency CAPEX and forecast price developments.

-

Introduction of sustainable measures to minimise risks

Sustainable measures are then derived from a medium- to long-term strategy to secure the entire supply network, such as the implementation of warehousing of critical parts throughout the supply chain, implemented in newly concluded contracts with suppliers.

-

Iterations and learning process

Behind the entire process, a central risk management system has been established in the purchasing department that regularly reviews the measures using KPIs and runs through the process at regular intervals. This ensures that risks are constantly reassessed and measures are adjusted.

The example shows the importance of risk management to make the supply chain resilient to crises - based on the use of digital technologies, a risk framework and central risk monitoring and governance.

Our sustainability expertise

Our expertise in digital technologies and sustainability helps our clients to solve environmental challenges.

The concept of DigiTainability advises how to combine technology & positive environmental impact to ensure a sustainable transformation.

What is to be done now?

A transparent, resilient and sustainable supply chain requires a new approach to anticipate future crises. This approach includes the following steps:

-

„Identify risks and determine impacts“: This can only be implemented cross-functionally (purchasing, logistics, operations, finance) and requires an evaluation of the entire supply network and a prioritisation of critical parts and suppliers using appropriate digital solutions.

-

„Implementing a resilient supply chain“:Corresponding measures to secure the supply chain must be derived, resulting in a new structure of the network. Here, the requirements for flexibility and cost orientation ("just-in-time") must be balanced with the necessary resilience and sustainability ("just-in-case").

-

„Transforming the supply organisation“: The end result is the implementation of a digitalised end-to-end process that maps the entire delivery network, as well as the introduction of central control and planning.

The more consistently these steps are implemented, the more effectively the supply chain is protected from crises and their risks.